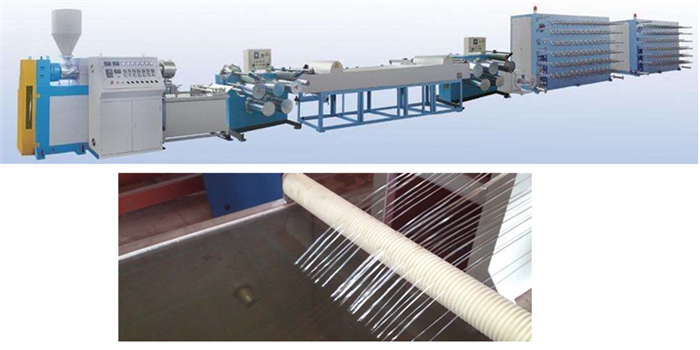

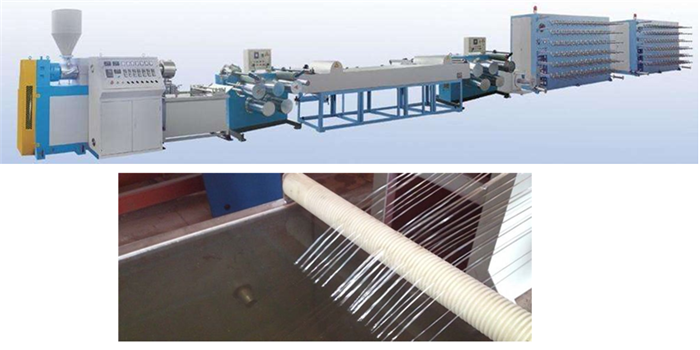

PET/PP flat filament Extrusion line

- Components It consists of special design of PET material dehumidifying and crystallizing system, extruder, screen changer, Melt pump, mold, haul-off, oven, and winder, etc. Production Process Material Dehumidifying and Crystallizing Extrudi

- Email:sales@sincere-extruder.com

Details

Components

It consists of special design of PET material dehumidifying and crystallizing system, extruder, screen changer, Melt pump, mold, haul-off, oven, and winder, etc.

Production Process

Material→ Dehumidifying and Crystallizing → Extruding → Filter→ Metering→ Mold → Cooling→ Haul-off →Oven Heating→ Haul-off→ Oven heating→ Haul-off → Glazing → Shaping → Haul-off→ Winding

Application

With 100% bottle flakes recycled material, to produce PET or PP flat monofilament, applied in vegetables and other agricultural product packaging, food packaging, geotechnical engineering, tourist transportation, daily necessities, etc. Like woven sack, chemical bag, foods bag, cement bag, leno bag, and jumbo bag.

Enquiry:PET/PP flat filament Extrusion line

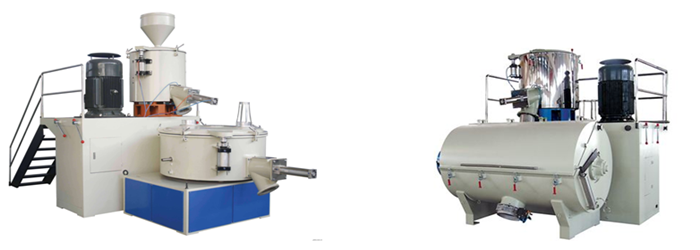

Auxiliary machinery

-

Other Auxiliary Units

-

Single shaft shredder

-

Heating/cooling mixing unit, SRL-Z Series

-

Crushers SWP Series

Popular Articles

- Plastic PVC Pipe Extrusion Machine

- The Differenc Between HDPE|PVC-U double wall corrug

- Plastic Pipe Machinery

- Plastic Machinery And Equipment History

+86-15726275773 E-mail:sales@sincere-extruder.com

Company address:266300 No.15 Jiangsu Road, Beiguan Industrial Park, city Jiaozhou, City Qingdao, China.