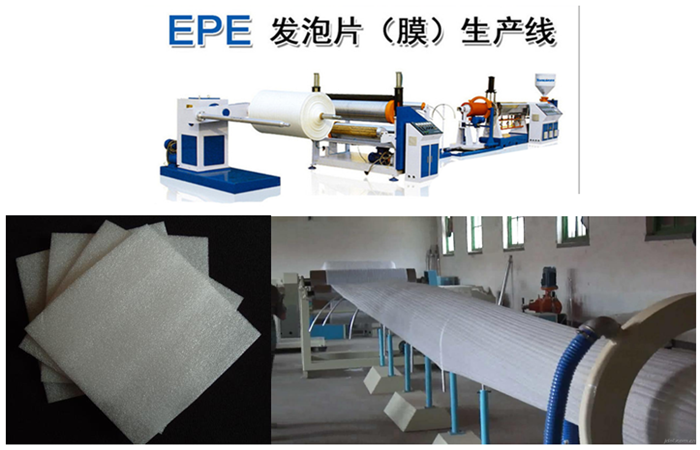

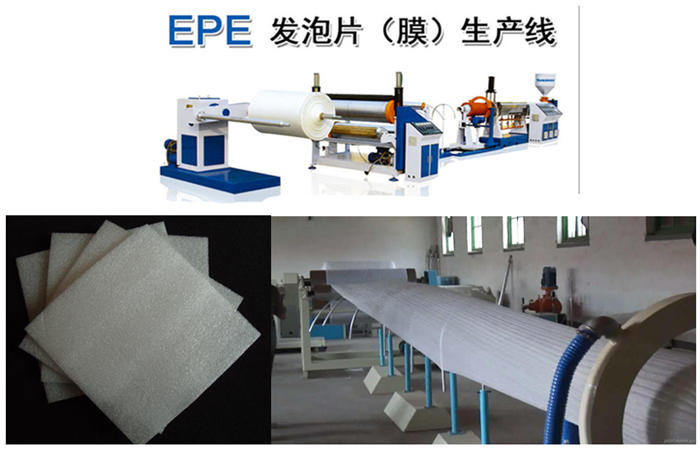

EPE foam sheet production line.

- Polyethylene foamed sheet ( film), is also named as pearlcotton, is a new type of packaging materials, with moisture, shock, noise, insulation, good plasticity and many other advantages, is the ideal alternative to traditional packaging mat

- Email:sales@sincere-extruder.com

Details

Polyethylene foamed sheet ( film), is also named as pearl cotton, is a new type of packaging materials, with moisture, shock, noise, insulation, good plasticity and many other advantages, is the ideal alternative to traditional packaging materials. Widely used in electronics, daily necessities, glass, ceramics, home appliances, spraying, furniture, metal products, toys and other products packaging.

EPE foam film production line using advanced stand-alone foaming process to meet international environmental standards for butane as a foaming agent, the production of products such as high magnification, white and delicate. Electrical control system selection of internationally renowned brands, explosion-proof motor, frequency control, energy efficient, safe and stable. Temperature control system to achieve intelligent digital control, and is equipped with cooling circulating water direct cooling barrel, temperature control more accurate, more responsive.

EPE foam film production line replacement head and the corresponding auxiliary machine can also produce foam tube, rod and other foam products, the real realization of a multi-purpose machine.

| Model | FPP-90 | FPP-105 | FPP-120 | FPP-135 | FPP-150 | FPP-180 | FPP-200 |

| Extruder | Ф90/55 | Ф105/55 | Ф120/55 | Ф135/55 | Ф150/55 | Ф180/55 | Ф200/55 |

| Screw speed(r|min) | 5-75 | 5-75 | 5-75 | 5-60 | 5-60 | 5-50 | 5-50 |

| Expansion ratio(times) | 20-45 | 20-45 | 20-45 | 20-45 | 20-45 | 20-45 | 20-45 |

| Product width | 1000-1400 | 1000-1600 | 1000-1600 | 1000-1600 | 1000-2000 | 1000-2000 | 1000-2000 |

| Product thickness | 0.5-3.0 | 0.5-5.0 | 0.8-6.0 | 2.0-8.0 | 2.0-12.0 | 3.0-16.0 | 3.0-25.0 |

| cooling method | Air-cooled, water-cooled | ||||||

| Installed capacity (approx.) | 90 | 100 | 120 | 140 | 150 | 180 | 280 |

| Dimensions (approx.) | 22*2.3*2.2 | 22*2.3*2.2 | 25*2.3*2.2 | 27*2.3*2.3 | 30*2.5*2.3 | 32*2.5*2.3 | 36*2.8*2.5 |

| Machine weight (approx.) | 8.5 | 9 | 10 | 12 | 15 | 17 | 20 |

Enquiry:EPE foam sheet production line.

Auxiliary machinery

-

Other Auxiliary Units

-

Single shaft shredder

-

Heating/cooling mixing unit, SRL-Z Series

-

Crushers SWP Series

Popular Articles

- Plastic PVC Pipe Extrusion Machine

- The Differenc Between HDPE|PVC-U double wall corrug

- Plastic Pipe Machinery

- Plastic Machinery And Equipment History

+86-15726275773 E-mail:sales@sincere-extruder.com

Company address:266300 No.15 Jiangsu Road, Beiguan Industrial Park, city Jiaozhou, City Qingdao, China.