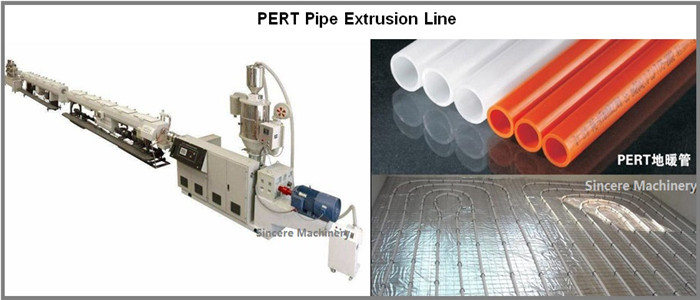

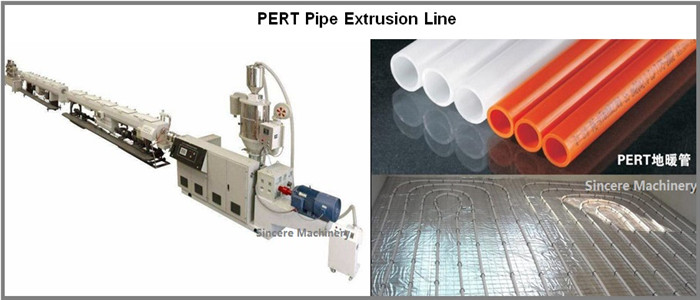

PERT floor heating pipe production line

- 1. Extrusion process: Plastic automatic loader Hopper plastic dryer Single screw extruder (Mark line extruder) Mould and calibrator Vacuum forming machine Water cooling tankHaul off machine Cutting machine stacker 2. Main Technical Specific

- Email:sales@sincere-extruder.com

Details

1. Extrusion process:

Plastic automatic loader →Hopper plastic dryer→ Single screw extruder (Mark line extruder)→ Mould and calibrator → Vacuum forming machine → Water cooling tank → Haul off machine → Cutting machine → stacker

2. Main Technical Specifications:

| Model | XSP/20-63 | XSP/75-110 |

| Pipe specifications (mm) | 20-63 | 75-110 |

| Main extruder | XSSJ-65*33 | XSSJ-75*33 |

| Assistant extruder | XSSJ-25*25 | XSSJ-25*25 |

| Output (kg/h) | 150 | 200 |

| Line speed (m/min) | 1-12 | 0.5-6 |

| Installed power (kw) | 80 | 100 |

| Outline size (L*W*H) | 26*2.5*2.8 | 32*2.5*2.8 |

Enquiry:PERT floor heating pipe production line

Auxiliary machinery

-

Other Auxiliary Units

-

Single shaft shredder

-

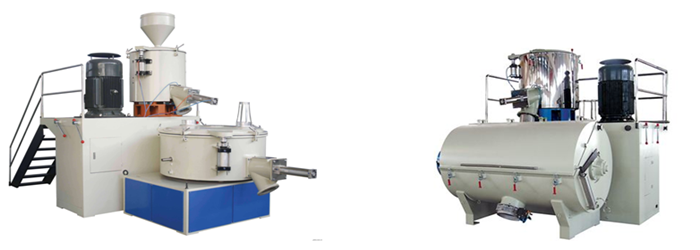

Heating/cooling mixing unit, SRL-Z Series

-

Crushers SWP Series

Popular Articles

- Plastic PVC Pipe Extrusion Machine

- The Differenc Between HDPE|PVC-U double wall corrug

- Plastic Pipe Machinery

- Plastic Machinery And Equipment History

+86-15726275773 E-mail:sales@sincere-extruder.com

Company address:266300 No.15 Jiangsu Road, Beiguan Industrial Park, city Jiaozhou, City Qingdao, China.